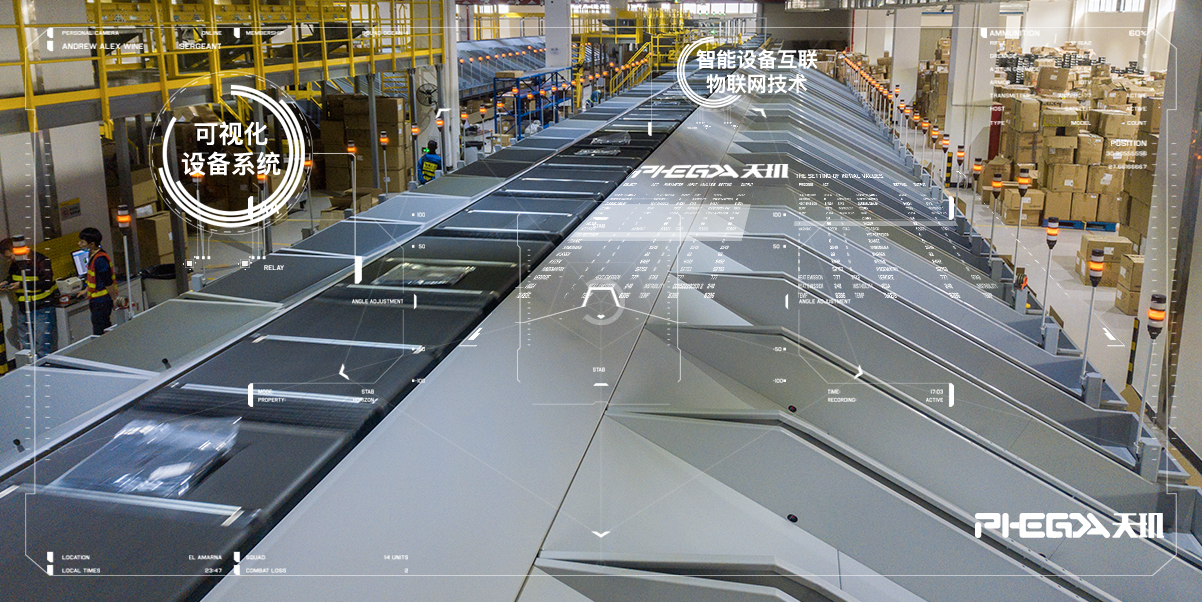

Phegda System

PHEGDA (PHM) System

is an advanced and intelligent prognostics and health management (PHM) system based on IoT, big data, cloud platforms, AI technologies and supported by information system platforms and hardware facilities. The system allows the connection of PLC, sensors, RFID, etc., which collect data and upload data onto the system on a real-time basis so that the system can sort out, mine, analyze the data, make prognostics, and offer suggestions for decision making. The system uses visual interfaces to provide users with an intuitive display of equipment operation status, truly offering real-time knowledge of equipment operation information.

can operate independently, and can also connect to WCS, MES, WMS, ERP, and other systems. It supports applications on both PC and mobile terminals and supports remote maintenance. The system has broken the traditional low-efficiency mode of the entire value chain covering data collection, summarization, classification, statistics, analysis, decision-making, etc., turning passive equipment maintenance into active and effective maintenance. The longer the system is used, the smarter and more experienced it becomes.

Product Features

Outstanding Artificial Intelligence

Monitor target equipment on a real-time basis, automatically collect, sort out, and classify equipment operation data around the clock

The unique AI-based intelligent algorithm easily mines and analyzes data among massive data

It provides specific queries, reports generation in a multi-dimensional environment, and supports data and chart exportPrognostics and Health Management

The signal sensor, PLC, and other hardware terminal data are synchronized and stored with PHEGDA (PHM) immediately to ensure precise, real-time system data

Real-time and precise data graphicalization intuitively presents the status, workload, and health condition of equipment

It provides recommendations on the decision-making of equipment health prediction and maintenance, supports remote maintenance, and significantly improves equipment efficiencySafe Ease of Use

The PC software coordinates the overall situation, and the mobile terminal ignores distance and regions. The servers are distributed at home and abroad to achieve global application deployment

It is easy to operate, with no need to manually enter equipment information or project data. It allows one-click project creation, which is convenient and accurate

Use advanced encryption technology to achieve independent management and control of member permissions. Classified storage of data and documents guarantees data securityConvenient Equipment Management

Implement distributed management of equipment of multiple projects and support fast construction of new project portals. Project information and equipment resources are clear at a glance

Self-service BI analysis maximizes the value of various project-related and equipment-related data

It provides multi-source data integration, reports statistics and data visualization, that allows such data to be viewed online and downloaded

-

Real-time monitoring

Real-time monitoring -

Intelligent mining

Intelligent mining -

Asset management

Asset management -

Visual charts

Visual charts

Model

System Architecture

Functional Module

Technical Architecture

Architectural Safety

Project Info

Project Board

Equipment Monitoring, Prediction, and Analysis

Equipment Health Records & Recommendations on Operation and Maintenance

報(bào)警管理

工單管理

Assets Management

Maintenance Plan

Project Homepage

Project Info

Equipment List

Alarm

Work order

Key data and task progress analysis

Equipment Online/Offline and Task Load Analysis

Equipment Duration and Analysis of Anomaly

Carton Shuttle System

Pallet Shuttle System

Picking Robot System

Robot Mini-Load system

Cross-belt Sorting System

AGV Intelligent Handling System

Vertical Conveyor System

i-Cube High-density Storage System

How Can We Help?

If you do have any question about our products and solutions, we are happy to communicate with you.

Contact us

Service Support

We provide you with the better advice and quick actions any time after purchasing our products.

Get help

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website.Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link.Read More